An R22 pressure temperature chart is an essential tool for HVAC technicians, providing a quick reference for determining the refrigerant’s state (liquid, vapor, or a mixture) based on its pressure and temperature. This chart is crucial for diagnosing refrigerant leaks, ensuring proper system charging, and optimizing the performance of air conditioning and refrigeration systems that use R22 refrigerant. Accurate readings from this chart are vital for efficient and safe system operation. Improper refrigerant levels can lead to reduced efficiency and potential damage to the system components. Understanding how to interpret an R22 pressure temperature chart is a fundamental skill for any HVAC professional.

The R22 pressure temperature chart works by illustrating the relationship between the refrigerant’s pressure and temperature under various conditions. By measuring the pressure and temperature at different points within the refrigeration cycle, technicians can identify potential problems. For example, a low pressure reading might indicate a refrigerant leak. Conversely, high pressure could signify a restriction in the system. The chart itself provides a visual representation of the saturation curve, which separates the liquid and vapor phases of the refrigerant. Understanding this curve is crucial for correct system diagnosis. Using the chart effectively allows for accurate troubleshooting and timely repairs, minimizing downtime and maintaining optimal system performance.

Accurate readings from a pressure temperature chart are vital for efficient and safe system operation. Understanding this relationship is crucial to diagnose issues correctly and fix them promptly, saving time and money. Using the chart correctly will help technicians avoid expensive repairs resulting from incorrect refrigerant charges or undetected leaks.

Understanding the R22 Pressure Temperature Chart

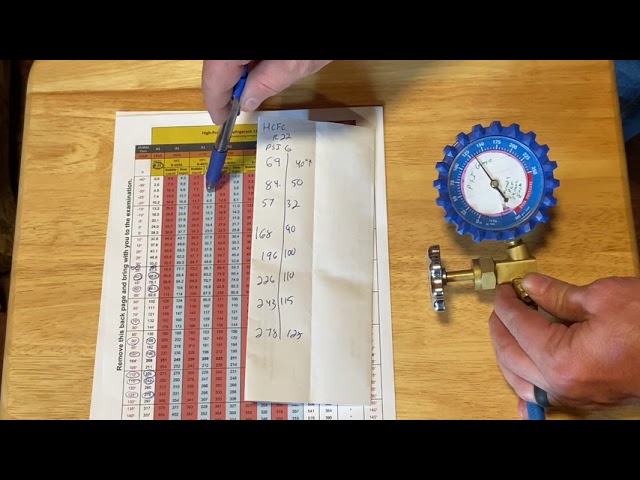

The chart’s design is based on the thermodynamic properties of R22. Each point on the chart represents a specific pressure and temperature, allowing for the determination of the refrigerant’s phase. The chart typically includes lines indicating the saturation pressure (the pressure at which the refrigerant changes phases), which is critical in determining the refrigerants state. Accurate readings are obtained by using calibrated gauges to measure both the high and low-side pressures. Understanding the chart’s format is essential for quickly assessing refrigerant charge and identifying potential problems within the refrigeration system. Effective use of this chart leads to more efficient troubleshooting and repair.

Furthermore, the chart helps technicians to determine the superheat and subcooling of the refrigerant. Superheat is the temperature difference between the actual refrigerant temperature and the saturation temperature at a given pressure. Subcooling, conversely, is the temperature difference between the saturated liquid temperature and the actual liquid temperature. Correct superheat and subcooling values are important indicators of a properly functioning system. Significant deviations from the ideal values point to potential problems within the system requiring attention.

-

Gather Necessary Equipment:

This involves obtaining calibrated pressure gauges, a thermometer, and the R22 pressure temperature chart itself. Ensure all equipment is in good working order and properly calibrated for accurate readings. Calibration ensures accuracy, reducing the likelihood of misinterpretations and resulting in efficient repairs. It’s also important to follow all safety precautions when working with refrigerants.

-

Identify System Access Points:

Locate the service ports on the high- and low-side of the refrigeration system. These ports are designed for connecting the pressure gauges for obtaining accurate pressure readings. Correct identification ensures safe and accurate readings. Incorrect identification can lead to inaccurate readings and possibly cause damage to the system.

-

Measure Pressure and Temperature:

Connect the pressure gauges to the service ports and measure the high- and low-side pressures. Simultaneously, measure the refrigerant temperature using a thermometer. Accurate measurements are vital for correct interpretation of the chart. Use calibrated equipment and follow the manufacturer’s instructions for optimal results. Inaccurate readings will lead to inaccurate conclusions.

-

Locate the Point on the Chart:

Using the measured pressure and temperature values, locate the corresponding point on the R22 pressure temperature chart. This point indicates the refrigerant’s state (liquid, vapor, or a mixture). Careful plotting of the point will determine the phase of the refrigerant and allow you to interpret the readings accurately. Errors in plotting can lead to misinterpretations.

Frequently Asked Questions about the R22 Pressure Temperature Chart

The R22 pressure temperature chart is a common source of questions for those working with R22 refrigerant systems. Many questions center around its interpretation and application, often arising from confusion about readings or a lack of familiarity with the underlying thermodynamic principles. Understanding its proper use is crucial for accurate diagnostics and efficient system maintenance. Consistent application leads to faster troubleshooting and more efficient repairs.

What are the limitations of an R22 pressure temperature chart?

While incredibly useful, an R22 pressure temperature chart has limitations. It primarily shows saturation conditions; it doesn’t directly account for superheat and subcooling beyond indicating those values. Ambient temperature can also affect readings, requiring adjustments for accurate interpretations. Moreover, the chart only provides data for R22; it’s not applicable to other refrigerants. Finally, the chart assumes a clean and well-functioning system; any blockages or other issues could render the pressure readings inaccurate.

How does ambient temperature affect the accuracy of readings?

Ambient temperature significantly impacts the accuracy of pressure readings. High ambient temperatures can cause the refrigerant to have a higher pressure than what the chart might indicate for a given temperature. Conversely, low ambient temperatures can have the opposite effect. Accurate temperature readings are, therefore, crucial for proper chart interpretation. This needs to be taken into consideration when conducting readings. Failing to do so may lead to incorrect diagnoses.

Why is it crucial to use calibrated gauges?

Using calibrated gauges is critical because inaccurate pressure readings will lead to incorrect interpretations of the chart and improper system adjustments. Incorrect refrigerant charge can lead to system inefficiency and potential damage. Regular calibration of gauges is crucial in maintaining their accuracy and ensuring that the charts data is correctly interpreted. Consistent calibration ensures that readings are reliable, leading to better diagnoses and repairs.

Key Aspects of an R22 Pressure Temperature Chart

The R22 pressure temperature chart is a fundamental tool for HVAC technicians. Its accurate application is essential for efficient and safe system operation. Understanding its nuances is vital for minimizing downtime and optimizing system performance. Proper usage leads to a more efficient and streamlined workflow.

Refrigerant Phase Identification

This aspect allows technicians to determine whether the refrigerant is a liquid, vapor, or a mixture of both. This helps in diagnosing leaks or other system faults and ensuring proper system charge. The chart is designed precisely for this purpose, which is a critical element in refrigeration system maintenance. The identification is the foundational step in any diagnostic process.

Saturation Curve Analysis

Analyzing the saturation curve helps technicians to understand the point at which the refrigerant transitions between phases and identify deviations from ideal operating conditions. This is central to proper refrigerant charge determination. Correct identification is pivotal in ensuring optimal system performance. Any deviation can pinpoint potential issues.

Superheat and Subcooling Measurement

The chart aids in determining superheat and subcooling values, which are essential indicators of system health and efficiency. These values provide further insight into the refrigerant’s condition within the refrigeration system. Accurate measurement of these parameters is essential to ensuring efficient system operation. Incorrect levels can signify system malfunctions.

Troubleshooting and Repair

The pressure-temperature relationship aids in identifying problems, such as leaks or restrictions within the refrigeration system. Accurate readings are essential for conducting repairs efficiently. This helps to avoid unnecessary replacements or costly repairs. The chart is a valuable troubleshooting guide, providing insights into malfunctions.

The charts effective use facilitates precise diagnosis of problems, leading to effective system repair and maintenance. The application of this knowledge is indispensable in modern HVAC practices. Understanding the chart’s utility prevents unnecessary component replacements and leads to cost-effective solutions.

Furthermore, the precise data offered by the R22 pressure temperature chart minimizes unnecessary work, ensures safety and optimizes performance. This ensures longevity of the system and prevents potential environmental hazards associated with refrigerant leaks. This information is crucial for ensuring both the efficiency and safety of the system.

Tips for Using an R22 Pressure Temperature Chart Effectively

Using the chart effectively requires understanding the basic principles of refrigeration and the relationship between pressure, temperature, and refrigerant phase. Accurate reading and interpretation of the charts data require careful attention to detail. Proper usage is essential to maintain system efficiency and prevent costly errors.

Always ensure that the equipment used is properly calibrated and maintained to ensure accurate readings. This will help eliminate false readings, enabling proper troubleshooting. A well-maintained toolset is important for generating accurate and reliable results.

Always use calibrated gauges.

This ensures accurate pressure readings are obtained, leading to a correct interpretation of the chart. Inaccurate gauges will result in misdiagnosis and potential system damage. Regular calibration is essential for maintaining accuracy.

Consider ambient temperature.

Ambient temperature can affect readings; account for this when interpreting the data to avoid misinterpretations and incorrect decisions related to system function. Accurate consideration of ambient conditions ensures correct readings.

Understand superheat and subcooling.

Knowing how to measure and interpret superheat and subcooling values is crucial for determining the health and efficiency of the refrigeration system. These are essential indicators of system performance. Accurate measurements prevent unnecessary repairs.

Consult the chart frequently.

Regular consultation helps technicians develop a better understanding of the refrigerant’s behavior and aids in rapid diagnostics. This enhances diagnostic capabilities and proficiency. Frequent use allows for a deeper understanding of system dynamics.

Use a reliable chart.

Utilize a reputable and well-established chart to ensure accuracy and consistency in data interpretation. Incorrect charts can lead to serious errors. Referencing reliable charts is crucial for data integrity.

The R22 pressure temperature chart is a powerful diagnostic tool; mastering its use is a critical skill for HVAC technicians. Proper application minimizes downtime and maximizes system efficiency. Continued practice and consistent application lead to enhanced proficiency.

Accurate interpretation of data from the chart allows for efficient troubleshooting and effective system maintenance. Understanding the chart is a fundamental skill for any technician working with R22 systems. This ensures the safe and efficient operation of the HVAC system.

In conclusion, the R22 pressure temperature chart remains an indispensable tool for any professional working with R22 refrigerant systems. Its proper and consistent use promotes efficient operation and long-term system health.

Youtube Video: